Abrasion Testing

Accelerated Life Testing

Chemistry Laboratory

Computer Modeling

Salt Spray Testing

Density

Electrical Properties

Electron Microscopy

Experimental Foundry

Failure Analysis

Hardness Laboratory

Heat Treatment Studies

Light Microscopy

Lubrication Testing

Machine Shop

Materials Databases

Mechanical Testing

Metallography

Paint & Coatings

Product Testing

Rolling Mill

Thermal Testing

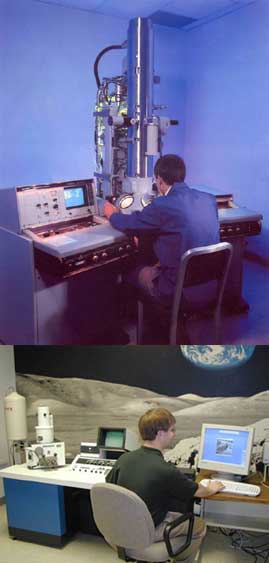

Electron Microscopy

Whatever your electron microscopy needs whether standard or unique Touchstone is here to help and at a cost below most laboratories.

SEM/TEM/FIBER PUSH-OUT SEM

For almost 20 years, Touchstone has been using electron microscopes for failure analysis, corrosion investigations, coatings development, quality control, and the development of new alloys and new composite materials.

Touchstone takes a unique approach to electron microscopy. Most laboratories only use electron microscopes to image samples, perform X-ray microanalysis, and in the case of TEM’s, perform microdiffraction. Touchstone, however, regularly builds unique test fixtures which can operate inside the electron microscope stage which provide direct solutions to a wide variety of industrial and R&D problems.

Among these has been; the development of a device which will measure the bond strength between the fiber and the matrix in composite materials; observing the micromechanics of small fasteners such as Velcro as they are engaged and disengaged; observing braze flow characteristics of new, vacuum-brazing alloys for the aluminum industry; and, tensile testing of small chopped fibers. Numerous other tests are possible such as micro-scale impact tests, and scratch tests on coatings.

Whatever your electron microscopy needs whether standard or unique Touchstone is here to help and at a cost below most laboratories.

Fiber PushOut SEM

To aid in the development of advanced composite materials, Touchstone has developed a unique apparatus for characterizing the fiber-matrix interface in composites. The interface bond and sliding characteristics are a critical parameter controlling composite behavior. The apparatus combines the high magnification and materials analysis capabilities of a scanning electron microscope (SEM) with a mechanical device for performing fiber push-out tests inside the SEM. Fibers in a thin section of a composite are loaded using an instrumented indenter which de-bonds and slides fibers out of the matrix material. The resolution and depth of field of the SEM makes alignment of the indenter possible even for the very small diameter fibers found in many of today’s composite materials. Elevated temperature push-out tests are also possible using a modified SEM hot stage. In addition, the instrument is capable of performing a myriad of other micro-mechanical tests.

Measurement Features include:

- Measures De-Bond Strength and Sliding Friction

- Tests Very Small Diameter Fibers (3microns + up)

- Load vs. Displacement

- Load vs. Time

- Digital Load and Acoustic Emissions Recording

- Videotape and Digital Image Capture

- Energy Dispersive X-ray Analysis of Interface

- Displacement Rates below 7.6 Micron/Minute

- Displacements Measured to Nanometers

- Elevated Temperature Tests to 1000° C

Touchstone developed and patented this device and has installed instruments of this design at EMPA, Thun – the Swiss Federal Laboratory; the Army Research Laboratory in Abberdeen, MD and the University of Southern California (USC).

Scanning Electron Microscopy (SEM)

The scanning electron microscopes at Touchstone are all equipped with energy dispersive spectrometer (EDS) systems. These provide a chemical analysis for any object such as inclusions that are seen on or in a sample being viewed inside the SEM. One SEM is capable of detecting all elements in the periodic table from the atomic number of sodium (11 AMU) and higher. Another SEM is equipped to also measure all elements from the atomic number of carbon (6 AMU) and above. Both qualitative and quantitative analyses are possible. In fact, there are numerous methods to provide quantitative analysis on our SEM’s including: ZAF, a standardless method; Matching, which involves using stored standard spectra for comparison, and standard based analysis. Touchstone has collected a wide range of standards for use in X-ray microanalysis, most of which were produced by NIST.

Computer software for the image analysis of particle size and number, grain size, and numerous other measurement.

SEM’s are, with certain materials and preparation, capable of resolving images of approximately 40 angstroms. This is usually what is quoted by manufacturers. In normal use conditions, SEM’s are limited in resolution by the samples being examined. The typical resolution found with steel or aluminum samples is in the range of 100 angstroms with useful magnifications of 20 to 30,000X.

Transmission Electron Microscope

Touchstone is equipped with a TEM capable of magnification to 300,000X and a resolution of approximately 10 angstroms. Applications include, viewing small precipitates in agehardenable alloys, grain boundaries, and dislocation networks. This equipment is also capable of selected area diffraction (SAD).

Sample preparation equipment include an ultramicrotome, jet polisher and a complete metallographic laboratory.