MetPreg™

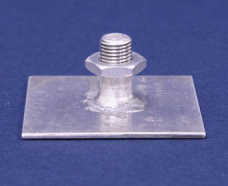

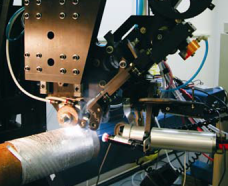

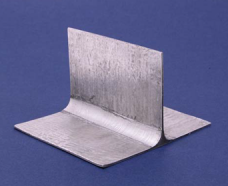

Touchstone’s MetPreg™ material system consists of FRA in “prepreg” form made from commercially available high strength/stiffness aluminum oxide fiber (such as Nextel 610) and an aluminum matrix. The FRA prepreg is in the form of a continuous thin tape that can be applied to a rotating mandrel in prescribed patterns using tape placement equipment and consolidated in situ via laser (thermal) brazing. This “cure-on-the fly” manufacturing process eliminates costly and time-consuming autoclaving and conventional thermal curing processes found in PMC manufacture.

This technology presents an opportunity to manufacture large MMC components through the use of production processes that are analogous to PMC processes while maintaining beneficial MMC materials properties. Components fabricated using this technique are affordable and sustain strength and stiffness at high temperatures. They are also easy to repair and to maintain.

This technology has broad applications within

Aerospace, Defense & Commercial Market sectors.

If you would like to know more about MetPreg™, please visit our website at www.metpreg.com.