Abrasion Testing

Accelerated Life Testing

Chemistry Laboratory

Computer Modeling

Salt Spray Testing

Density

Electrical Properties

Electron Microscopy

Experimental Foundry

Failure Analysis

Hardness Laboratory

Heat Treatment Studies

Light Microscopy

Lubrication Testing

Machine Shop

Materials Databases

Mechanical Testing

Metallography

Paint & Coatings

Product Testing

Rolling Mill

Thermal Testing

Experimental Foundry

Our suite of modeling capabilities includes Pro ENGINEER®, AutoCAD®, SolidWorks®, and ANSYS®.

The heart of Touchstone’s foundry area is a 50 KW solid-state coreless induction furnace with graphite crucible for melting up to 45 pounds of aluminum or other non-ferrous alloys. This capability can be used by larger foundries to avoid down time in their production schedule or by scientists and engineers that are working on research projects for improving the properties of aluminum alloys. Current ingot casting capacity includes 8” X 2” X 20” and 4” X 4” X 20” molds.

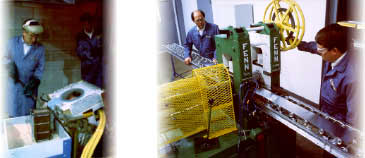

Rolling Mill

Touchstone can also reduce aluminum to plate or sheet using a 10-inch wide reversing hot mill and an 8-inch wide reversing cold-rolling mill that is currently equipped with 5-inch diameter tool-steel rolls. The cold mill has coiling capability and can roll aluminum to 0.010-inch gauge sheet. This equipment is ideal for producing small quantities of experimental aluminum sheet for laboratory trials with coils up to 350 feet in length. The rolling mills can also be used to support studies of cold reduction of various aluminum alloys to produce plots of mechanical properties versus percent reduction. The system is also capable of producing sheet to support experimental stamping trials. Each mill has a 100,000 pound maximum closing force and can cold roll a wide range of metals.

Heat Treatment

Touchstone also has the capability to perform heat treatment of aluminum alloys, including solution heat treating, quenching, precipitation heat treating, and artificial aging. This work is further supported by metallography, mechanical testing, chemistry, and electron microscopy capabilities.