Corrosion Potential Testing (ASTM G 69)

Abrasion Testing

Accelerated Life Testing

Chemistry Laboratory

Computer Modeling

Salt Spray Testing

Density

Electrical Properties

Electron Microscopy

Experimental Foundry

Failure Analysis

Hardness Laboratory

Heat Treatment Studies

Light Microscopy

Lubrication Testing

Machine Shop

Materials Databases

Mechanical Testing

Metallography

Paint & Coatings

Product Testing

Rolling Mill

Thermal Testing

ACCELERATED LIFE TESTING

ACCELERATED LIFE TESTING

Touchstone performs corrosion testing and accelerated life testing of virtually any material or device. Among the tests offered are:

- Cathodic Disbondment (ASTM G 80, G 95)

- Cleveland Condensing Humidity (ASTM D 4585)

- Corrosion Potential (ASTM G 69)

- Fluorescent UV (ASTM G 53)

- Paint & Coatings Tests

- Pressurized, Accelerated Life Testing

- Pressurized Testing of Heat Exchangers (Radiators, Evaporators and Condensers)

- Test Panel Evaluation (ASTM D 1654)

- Water Resistance and Humidity (ASTM D 870, ASTM D 2247)

SALT FOG AND SALT SPRAY TESTING

- CASS – Copper Accelerated Acetic Acid Salt Spray (ASTM B 368)

- Salt Spray (Salt Fog) (ASTM B 117)

- ASTM G85 Tests

Customized Environment

Corrosion Potential Testing (ASTM G 69)

To request a quotation for any test e-mail info@trl.com for a prompt reply

The ASTM G69 method measures the corrosion potential of aluminum alloys. Corrosion potential is also known sometimes as “solution potential”, “rest potential” or the “open-circuit solution”. It has been used for more than 50 years to verify the temper of aluminum (Al) alloys. It is also a useful tool for characterizing the metallurgical condition of aluminum alloys, particularly 2XXX and 7XXX, whose major alloying elements are copper and zinc. Although corrosion potential is not the same as corrosion rate, it can be used to determine if galvanic corrosion will occur when different metals and alloys are connected in an environment of aerated saltwater.

Sample/specimen preparation is important and can be done by Touchstone. If you prepare your own samples, you must ensure during sawing/stamping you do not change the metallurgical structure from heat. Specimen size is not important, provided the area is at least 25 mm2. Ease of handling is a consideration, however, so samples a few millimeters thick by about 15 mm wide and 100 mm long are recommended. At least two, and possibly three specimens, are needed for each alloy to be evaluated.

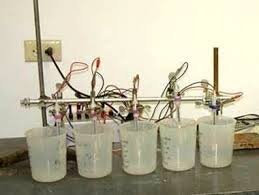

Samples are exposed to a salt water/peroxide medium along with a saturated calomel electrode. A sample of 3003 aluminum sheet is run concurrently with each test as a reference sample. The corrosion potential data, in millivolts, is collected. The brazing industry has a specification not just in corrosion potential, but in the change in potential through the thickness of the brazed sheet.

The standard practice has been to remove layers of metal by exposure of the aluminum brazing sheet to strong caustic solution and timing the reaction so that only a certain amount of metal is removed. This practice suffers from being uncontrolled and unpredictable. Sometimes the sample was destroyed, thus losing valuable data. Touchstone Research has improved on this method by developing a technique for removal of minute amounts of surface material in a predictable manner. As little as 0.0005″ can be removed at one step.

Additional corrosion tests are available, as well as light microscopy, scanning electron microscopy, metallography, failure analysis, and mechanical testing services.

Reference: ASTM G69: Standard Test Method for Measurement of Corrosion Potentials of Aluminum Alloys