Abrasion Testing

Accelerated Life Testing

Chemistry Laboratory

Computer Modeling

Salt Spray Testing

Density

Electrical Properties

Electron Microscopy

Experimental Foundry

Failure Analysis

Hardness Laboratory

Heat Treatment Studies

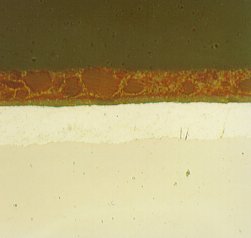

Light Microscopy

Lubrication Testing

Machine Shop

Materials Databases

Mechanical Testing

Metallography

Paint & Coatings

Product Testing

Rolling Mill

Thermal Testing

ACCELERATED LIFE TESTING

Cathodic Disbondment Testing (ASTM G 80 and ASTM G 95)

For a prompt reply and quotation on any test, e-mail info@trl.com or call 304-547-5800.

This method is used to evaluate the long-term performance of barrier coatings used to protect metal pipe used in underground applications. The test consists of placing a test specimen coated with the candidate material in series with a magnesium anode as part of a galvanic cell. The electrolyte is a mixture of various salts including NaCl, KCl, and sodium bicarbonate.

Prior to placement in the electrolyte the coating is intentionally damaged (holiday) in one or more locations to provide a site where edge corrosion may occur. The sample is then allowed to remain in the electrolyte for 30 days after which time the edges of the holiday(s) are evaluated to determine the extent of disbondment.

References: ASTM G80 – Standard Test Method for Specific Cathodic Disbonding of Pipeline Coatings; ASTM G95 – Standard Test Method for Cathodic Disbondment Test of Pipeline Coatings (Attached Cell Method)

Accelerated Life Testing

Touchstone performs corrosion testing and accelerated life testing of virtually any material or device. Among the tests offered are:

- Cathodic Disbondment (ASTM G 80, G 95)

- Cleveland Condensing Humidity (ASTM D 4585)

- Corrosion Potential (ASTM G 69)

- Fluorescent UV (ASTM G 53)

- Paint & Coatings Tests

- Pressurized, Accelerated Life Testing

- Pressurized Testing of Heat Exchangers (Radiators, Evaporators and Condensers)

- Test Panel Evaluation (ASTM D 1654)

- Water Resistance and Humidity (ASTM D 870, ASTM D 2247)

Salt Fog and Salt Spray Testing

- CASS – Copper Accelerated Acetic Acid Salt Spray (ASTM B 368)

- Salt Spray (Salt Fog) (ASTM B 117)

- ASTM G85 Tests

Customized Environment

We perform many other accelerated life/corrosion tests and can develop tests that evaluate performance of materials in your environment of interest. Please call or e-mail us with your request.