Paint and Corrosion Adhesion Testing

Abrasion Testing

Accelerated Life Testing

Chemistry Laboratory

Computer Modeling

Salt Spray Testing

Density

Electrical Properties

Electron Microscopy

Experimental Foundry

Failure Analysis

Hardness Laboratory

Heat Treatment Studies

Light Microscopy

Lubrication Testing

Machine Shop

Materials Databases

Mechanical Testing

Metallography

Paint & Coatings

Product Testing

Rolling Mill

Thermal Testing

PAINT AND COATINGS LABORATORY

- Abrasion Testing

- Accelerated Life Testing

- Adhesion Testing

- Chemistry Analysis

- Corrosion Protection

- Failure Analysis

- Film Hardness Testing

- Film Thickness Measurement

- Formability Testing

- Gloss Measurement

- Heat Resistance Testing

- Solvent Testing

- Standard Applications Testing

- Impact Testing

- Volatiles – Total

- Volume Solid

Paint and Corrosion Adhesion Testing

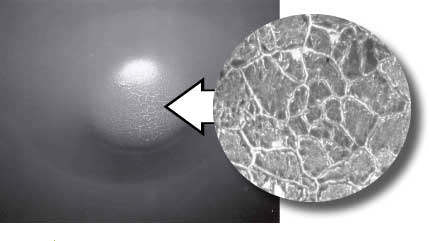

Coating Specimen After Impact Testing

Coating Specimen After Impact Testing

Touchstone’s Mechanical Testing Laboratory offers a variety of both standard and custom tests which can be used to measure resistance to cracking (flexibility) and adhesion of attached organic coatings on substrates of sheet metal or rubber-type materials. Among them are:

- Direct and Reverse Impact Test (ASTM D2794) [Shown above]

- T-Peel Test

- Direct Tensile Testing (ASTM D5179)

- Mandrel Bend Tests (ASTM D522)

- Olsen Cup Tests

- Bend Test (ASTM D4145)

- Peel Test (ASTM B571)

- Tape Test (ASTM D3359) [Described below]

Measuring Adhesion by Tape Test (ASTM D 3359)

“Standard Test Method for Measuring Adhesion by Tape Test”

ASTM D3359 provides two test methods for assessing the adhesion of coating films to metallic substrates by applying and removing pressure-sensitive tape over cuts made in the film.

In Test Method A, an “X-cut” is made in the film to the substrate, pressure-sensitive tape is applied over the cut and then removed, and adhesion is assessed qualitatively on a 0 to 5 scale.

In Test Method B, a lattice pattern with either six or eleven cuts in each direction is made in the film to the substrate, pressure-sensitive tape is applied over the lattice and then removed, and adhesion is evaluated by comparison with descriptions and illustrations.

Method A is primarily intended for use at job sites, while Method B is more suitable for use in the laboratory. The cross-hatch test, Method B, is not considered suitable for films thicker than 5 mils (125 micometers).